Determining the Resistance to Water Washout of Lubricating Greases

Water Washout Remedies for Lubricating Greases

Cold rolling steel mills have historically used greases formulated with simple lithium soap, lithium calcium mixed soaps, and lithium complex thickeners. Overbased calcium sulfonate greases are a recent addition and are becoming a lubricant of choice for the bearings used to support the rollers. Water intrusion into the grease is a challenge for these bearings as it can form an emulsion with the grease base oil leading to a loss of grease structure and consistency.

PRODUCT SPOTLIGHT

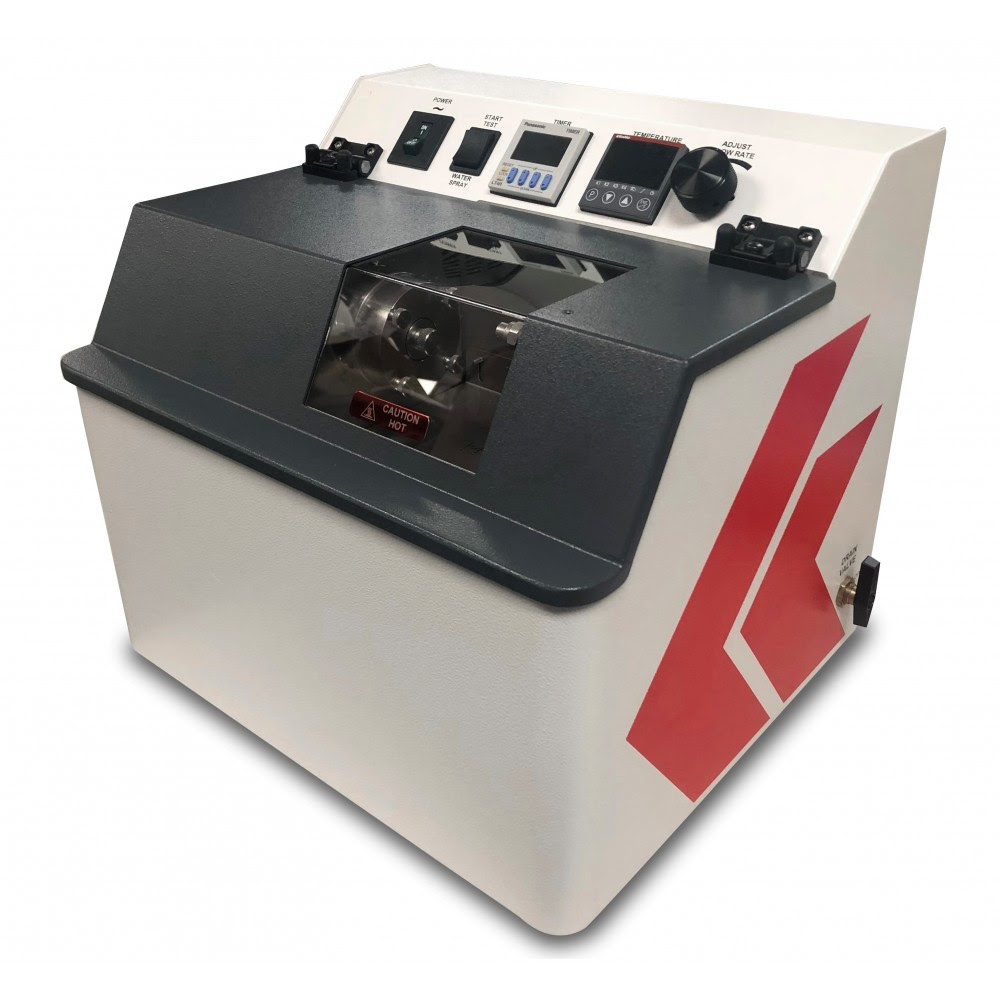

Water Washout Tester K19201

The Koehler Digital Water Washout Tester rotates a lubricated ASTM ball bearing at 600rpm in a modified bearing/housing assembly while impinging the bearing with a jet of water at the specified flow rate and temperature. The tared bearing and bearing shields are weighed before installation in the bearing housing and again after testing and drying to determine the amount of sample loss. The tester consists of a reservoir, bearing housing, circulation system and drive motor.

The Koehler Water Washout Tester is designed to determine resistance to water

washout of greases according to ASTM specifications

Conforms to the specifications of ASTM D1264, D4950; IP 215; FTM 791-3252

- Consists of reservoir, bearing housing, circulation system and drive motor

- Reservoir is equipped with cartridge heater, thermoregulator and thermometer port for accurate temperature control at 100°F and 175°F (38°C and 79°C) per ASTM specifications

- The rugged 1⁄3hp drive motor rotates test bearing at 600rpm while driving the circulation pump

- A two-pulley system permits independent pump operation to circulate water while heating it to test temperature